Hi

Currently we are working on the manufacturing roadmap, we have identified few features which are as below.

Production Planning

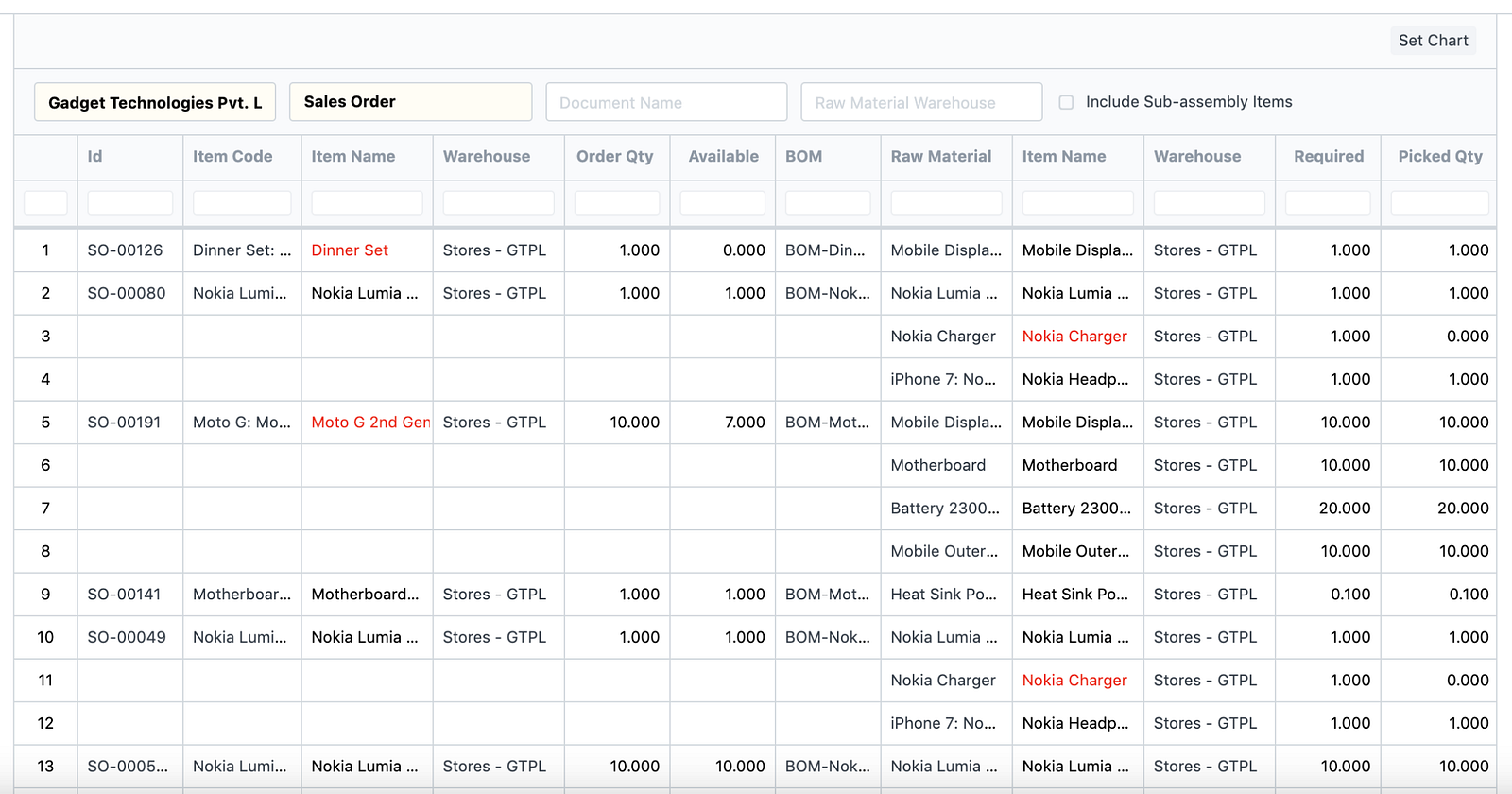

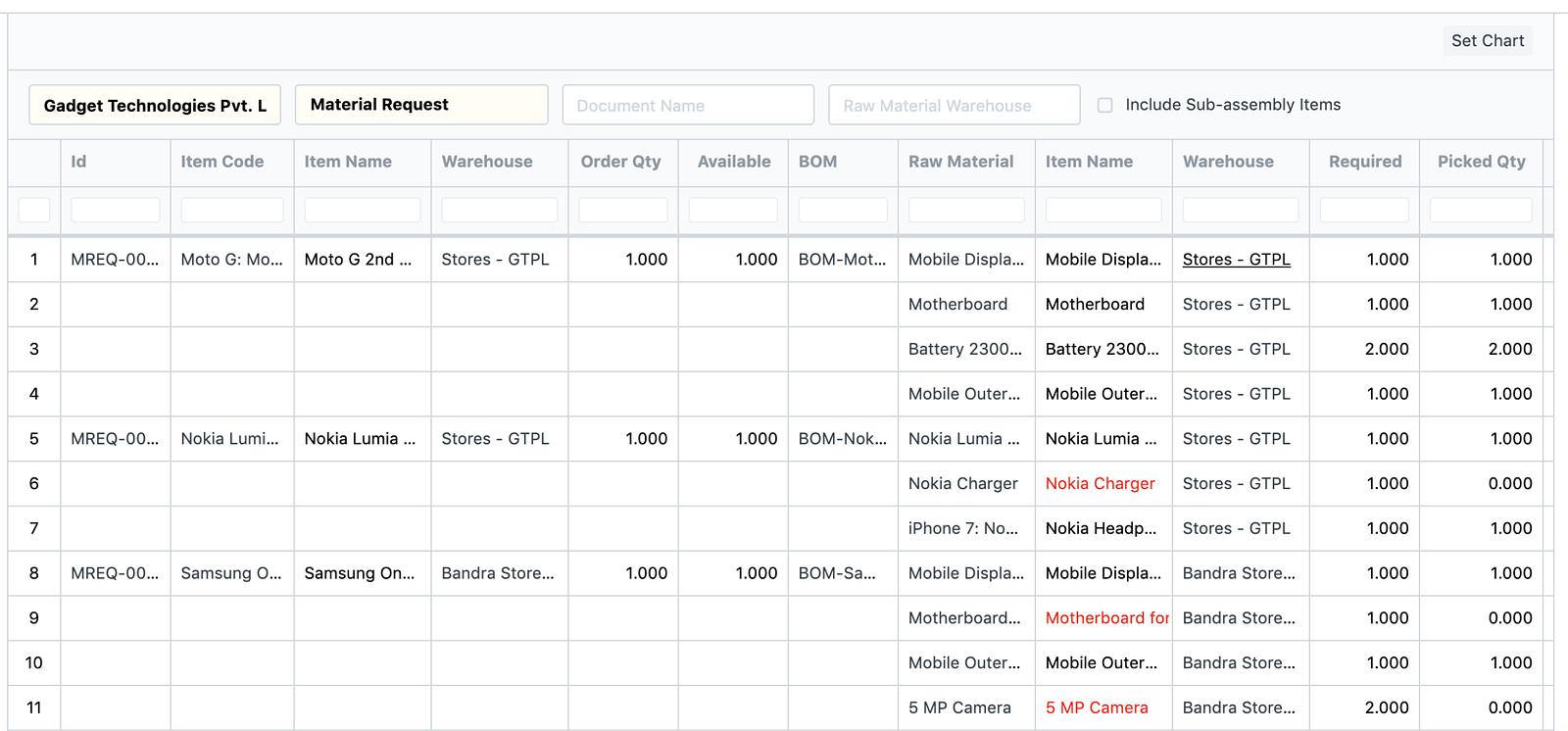

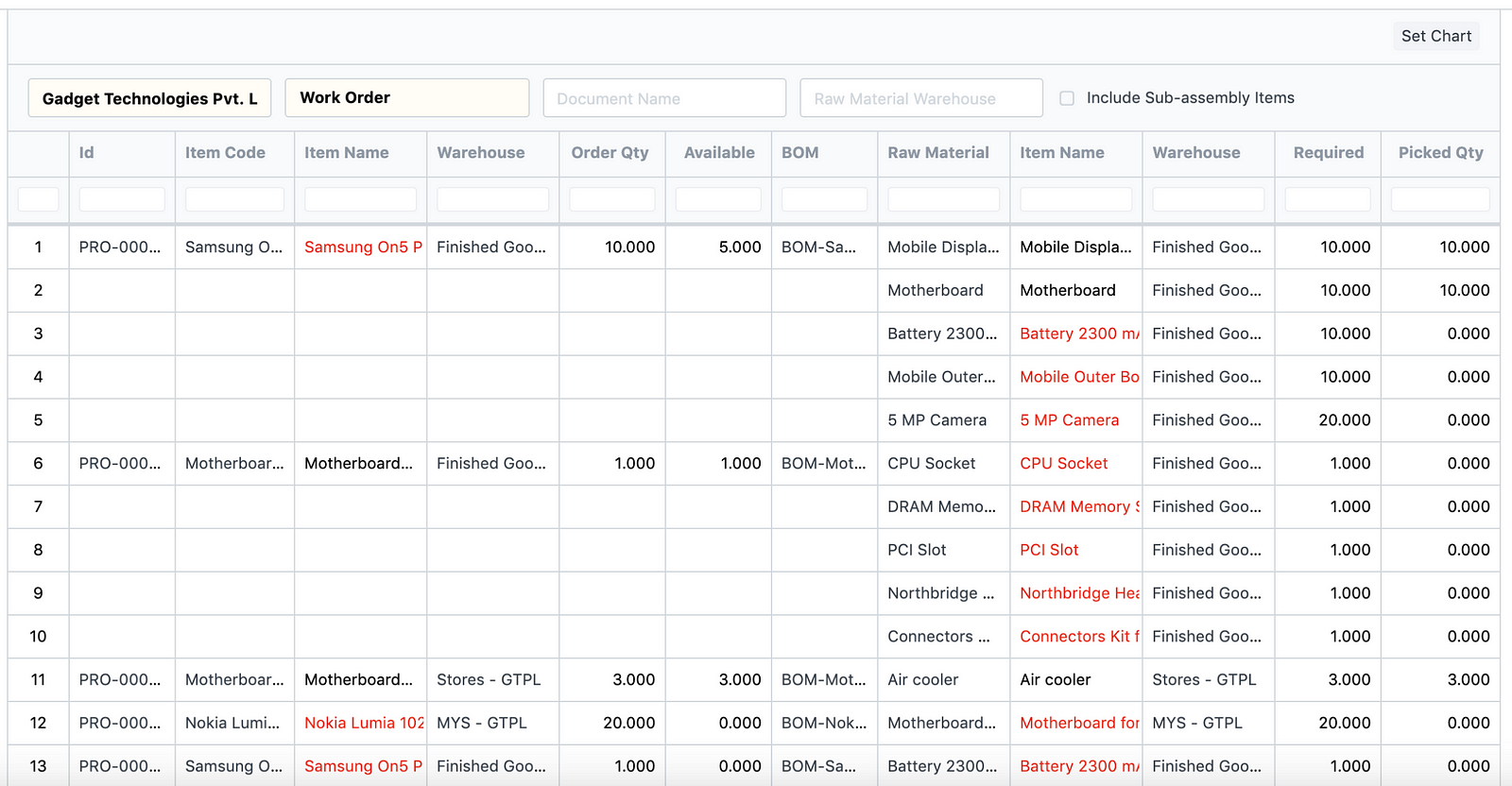

Make to order based manufacturing companies needs to do production planning of the raw materials. We have built a report which will give the information about available quantity of the finished goods and the raw materials. User can do the production planning against the open sales orders, open materials requests(with type as Manufactured) and open work orders.

Based on Sales Order

Based on Material Request

Based on Work Order

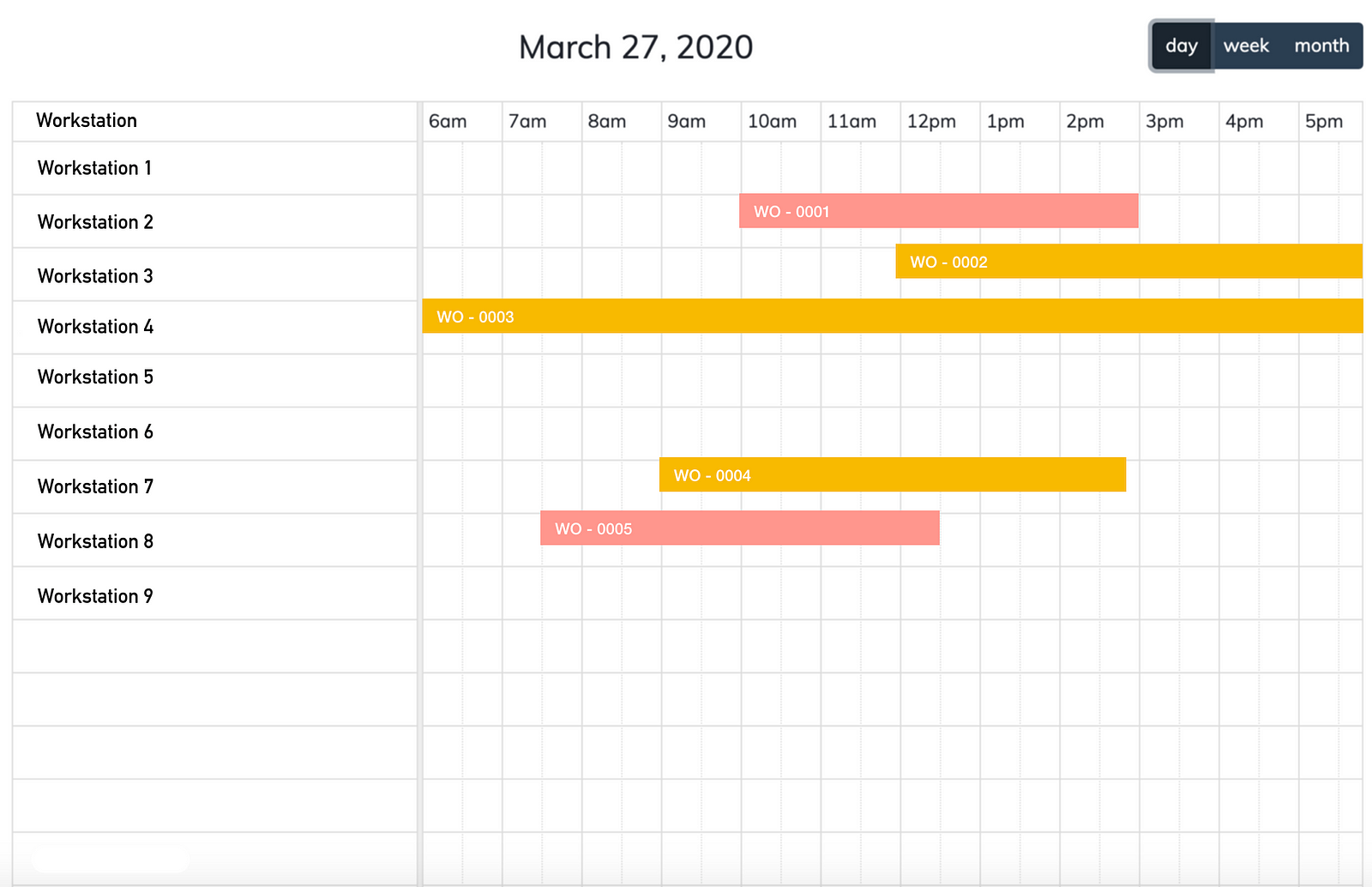

Scheduling

Scheduling is important for the manufacturing industry to understand the workstations / machines load as well the lead time requires to complete the finished goods. In ERPNext, based on the operations defined in the BOM we do scheduling. The Job card will be create based on the BOM Operations in which expected start time and end time will be calculate based on the time defined in the BOM. We are planning to add the calendar which will tell users that workstation wise allocation of the work orders and the operations.

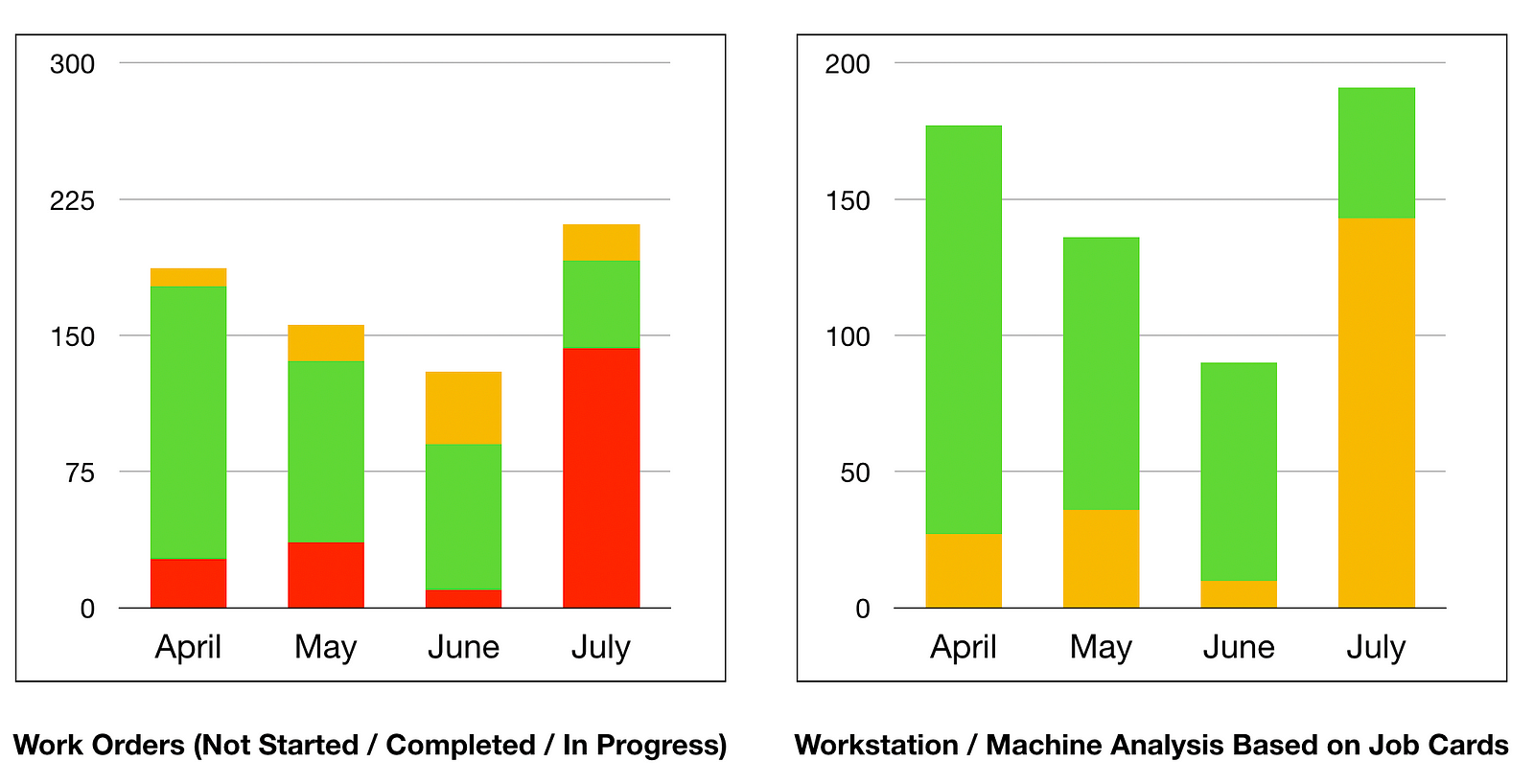

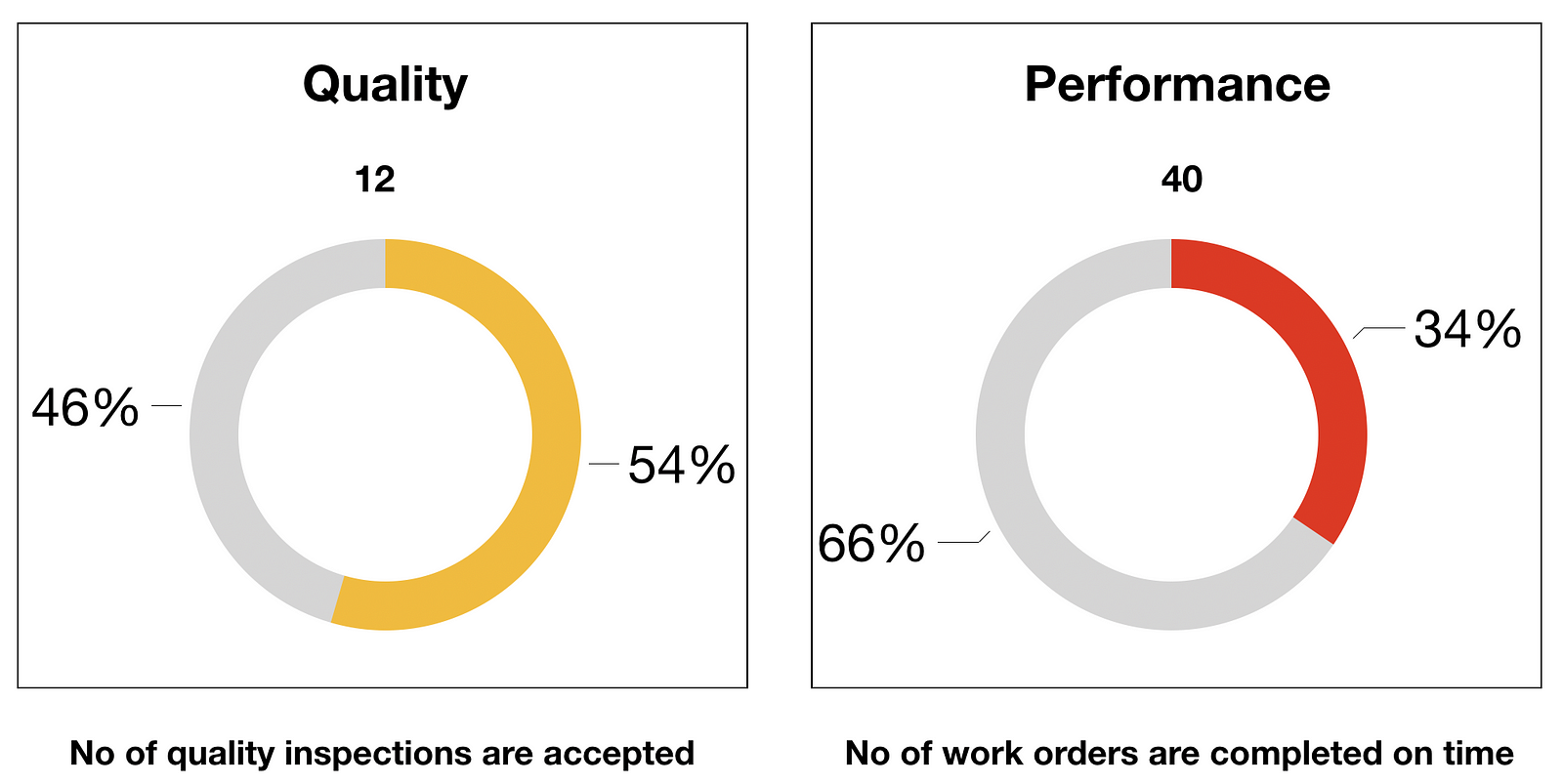

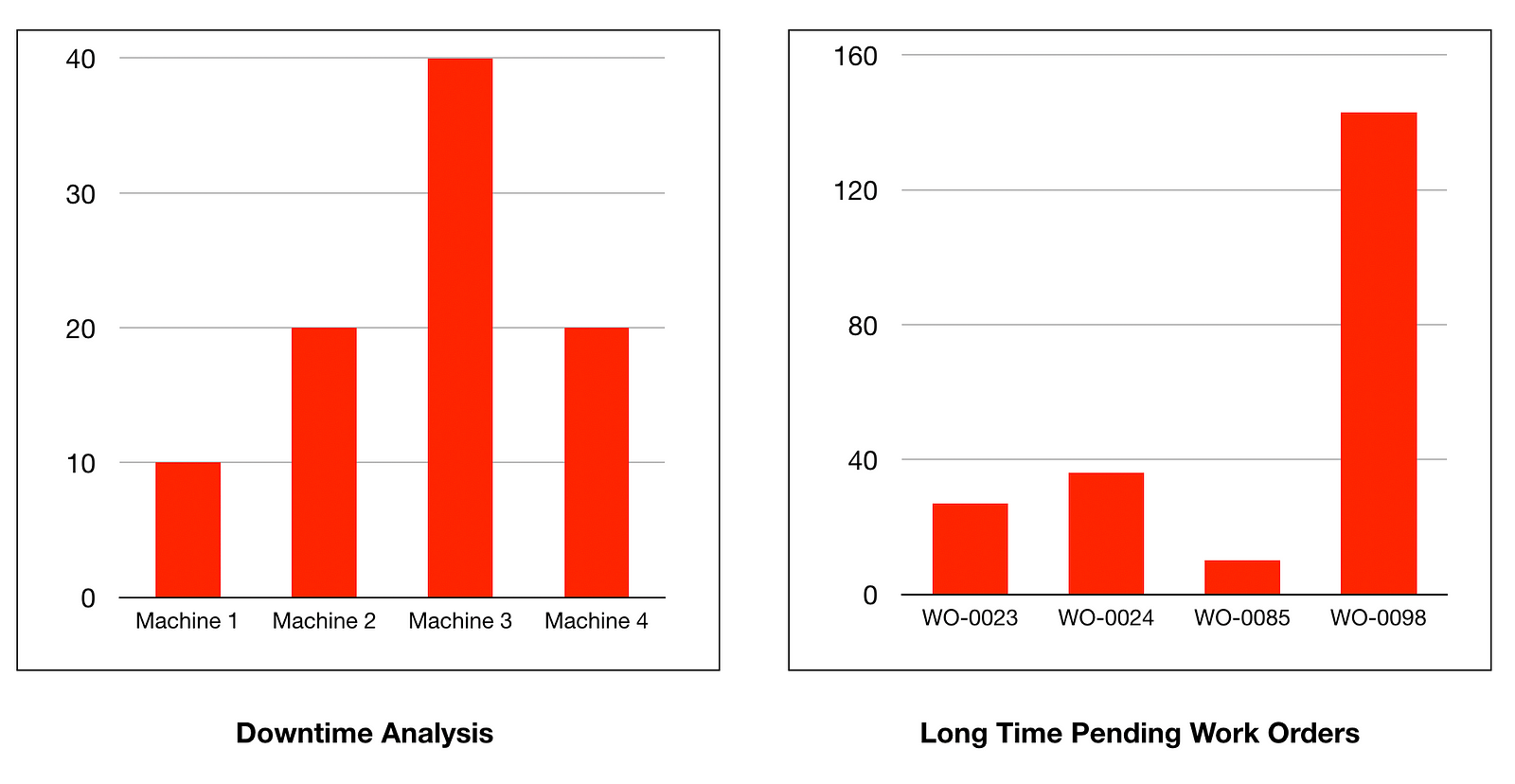

Dashbaord

ERPNext don’t have the dashboards for the manufacturing module, below is the list of dashboards we have finalized for the roadmap.

Downtime

To capture the downtime of the machine we will add the doctype using which users will understand which workstation/machine has maximum downtime.

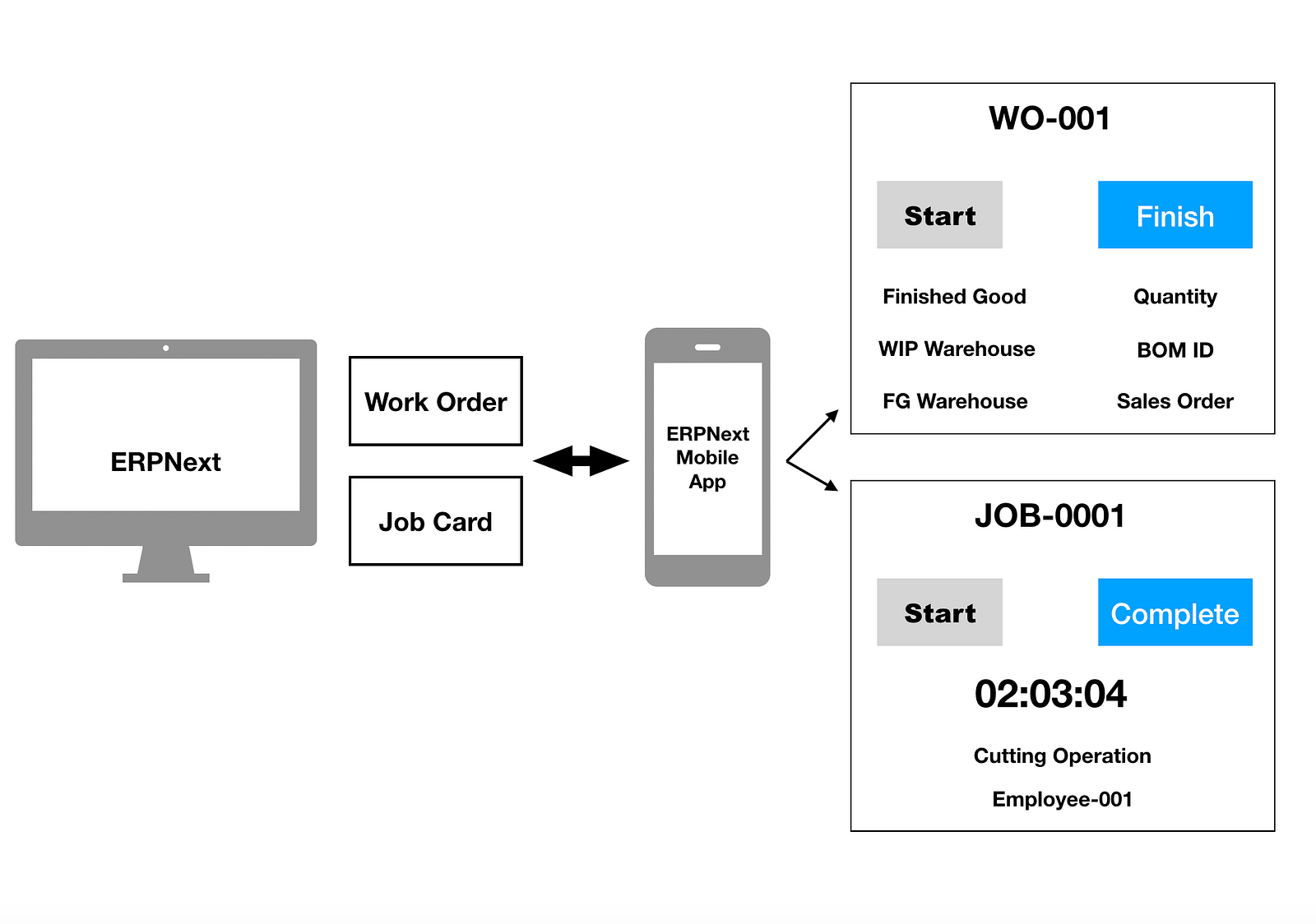

Manufacturing Execution System

Every manufacturing company has one common problem is that a data entry in the system. To make it simple we are thinking to create a mobile app for the manufacturing module. The Work Orders / Job Cards can be complete using the mobile device. Also using mobile app operator can consume the raw materials against the Work Order / Job Card.

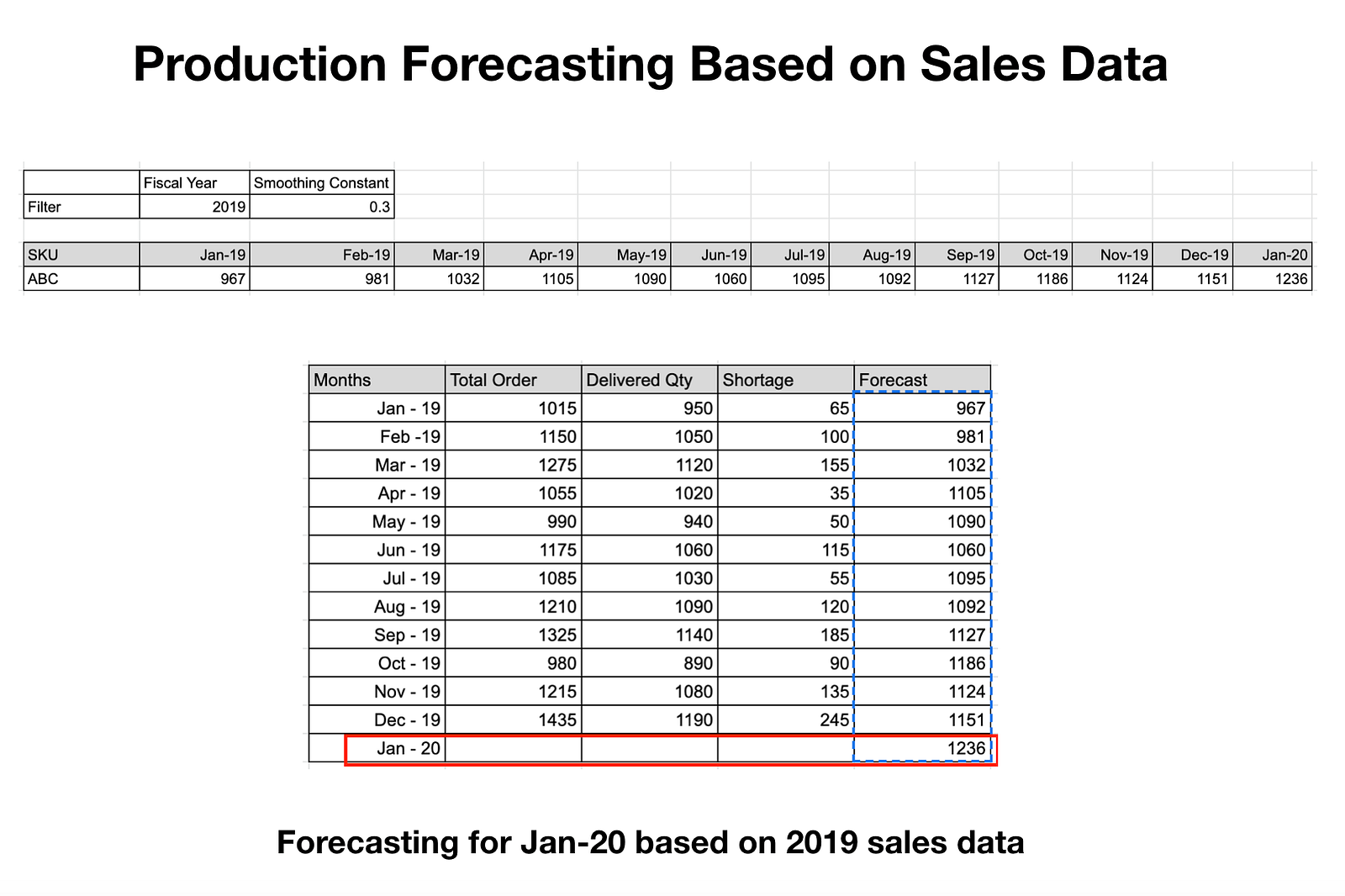

Inventory Forecasting

Inventory forecasting is helpful for the manufacturing industry which follows the make to stock method. Based on the sales data of the last year we can forecast the inventory for the upcoming month, below is the example (Using exponential smoothing method).

Kindly share your feedback.