Hi Ben,

May I please use this discussion-thread to converse about another problem in Manufacturing.

I am stating the problem in details. Please go through it and help me with a solution.

We created a Sales Order (SO-00001) for FG-Item-A for 1 quantity.

We used the Production Planning Tool (PPT) to create the Production Order (PRO-00001) for 1 quantity of FG-Item-A. PRO-00001 was created in ‘Draft’ status.

FG-Item-A consists of 2 Sub-Assemblies and 3 Raw Materials.

Out of these, the 2 Sub-Assemblies are manufactured in our Shop-Floor-1. The Raw Materials required for maufacturing these two Sub-Assemblies are stored in Stores-1.

In Shp-Floor-2, we assemble these 2 Sub-Assemblies along with 3 other Raw Materials. These 3 Raw Materials are stored in Stores-2.

NOTE: There are NO raw Materials in stock.

NOTE: Capacity Planning is disabled.

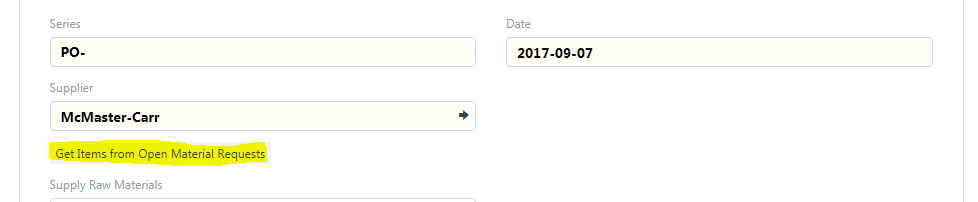

Next, we created the Material Requests (MR) for SO-00001, using the PPT.

We chose the option ‘Use Multi-Level BOM’ = Yes.

We selected the Store = Stores-1.

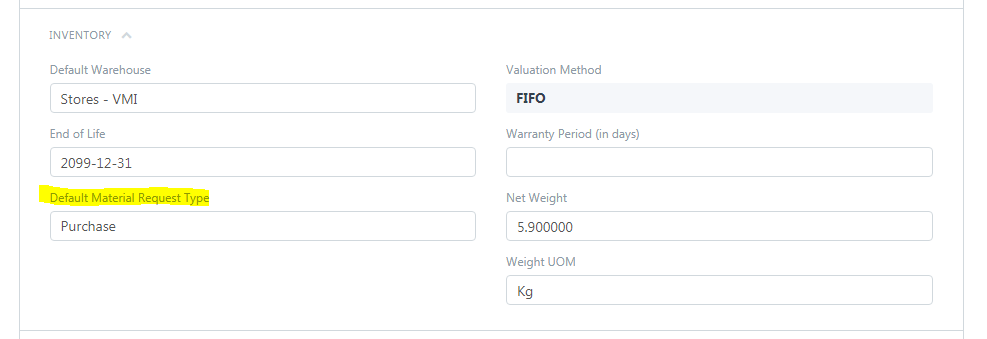

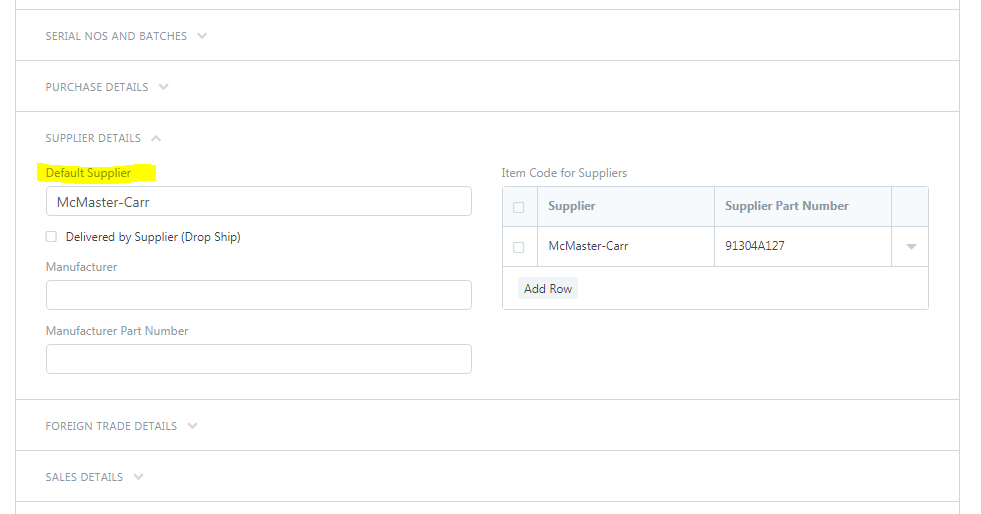

As a result, the system created the Material Requests (MR) for all the Sub-Assemblies and the Raw Materials defined in the BOM for FG-Item-A. The Material Requests for the Sub-Assemblies are of Type = Manufacture and the MRs for the Raw Materials are of Type = Purchase.

All the Material Requests are generated for Stores-1.

We checked the Material Requests and all of them are linked to the Sales Order SO-00001 by the system.

We created another Sales Order (SO-00002) for a different Customer for 1 quantity of the same item FG-Item-A.

We used the PPT to create a Production Order (PRO-00002) for 1 quantity of FG-Item-A.

PRO-00002 was created in ‘Draft’ status.

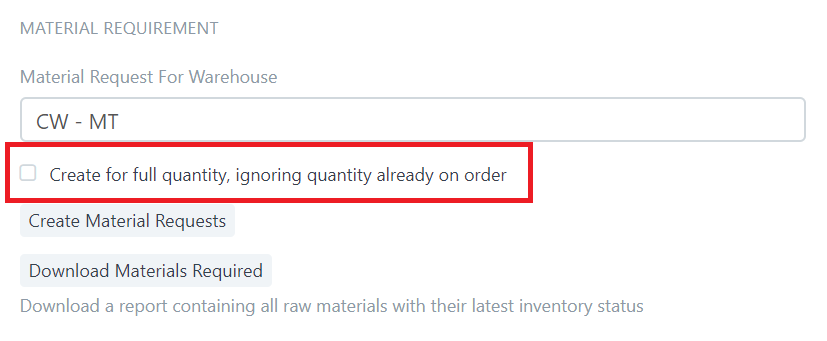

We tried to create the Material Request for SO-00002 using the PPT. We chose the option ‘Use Multi-Level BOM’. We chose Stores = Stores-1.

But the issue is that the system comes up with the message – Nothing to request.

Since we have a New Sales Order (SO-00002), the system should have created another set of Material Requests to support this Sales Order SO-00002; but, no Material Requests were created.

NOTE: We are using ERPNext: v8.8.1 (master); Frappe Framework: v8.7.3 (master)